Introduction

In today’s logistics landscape, packaging is far more than a box. With e‑commerce driving millions of parcels to homes and businesses every day, procurement and sustainability managers must ensure products arrive intact while minimizing environmental impact and cost. A Bryant Chrystie report states that Canada alone generates over 3 million tonnes of plastic waste each year, almost half of which comes from packaging. Government data show that Canadians threw away 4.4 million tonnes of plastic waste in 2019 and only 9 % was recycled. These figures underscore why organizations across Canada are embracing sustainable packaging practices.

Void fill, the material placed inside a package to stop movement and absorb shock, is a critical part of protective packaging. Two dominant approaches are air cushion (inflatable plastic pillows) and paper void fill (crumpled or padded paper). This article compares their benefits, limitations and sustainability credentials so you can choose the best option for your Canadian business. Throughout the article, statistics and trends are cited from credible sources and tailored to the needs of procurement and sustainability managers.

Understanding Void Fill Solutions

What Is Void Fill?

Void fill refers to materials used to occupy empty space in shipping cartons, preventing items from shifting and absorbing shock during transit. Ranpak defines void fill as “paper filler material used to close up the free space in your shipping box and lock products in place”. Without proper void fill, packages may arrive damaged, increasing returns, waste and customer dissatisfaction.

Air Cushion Void Fill

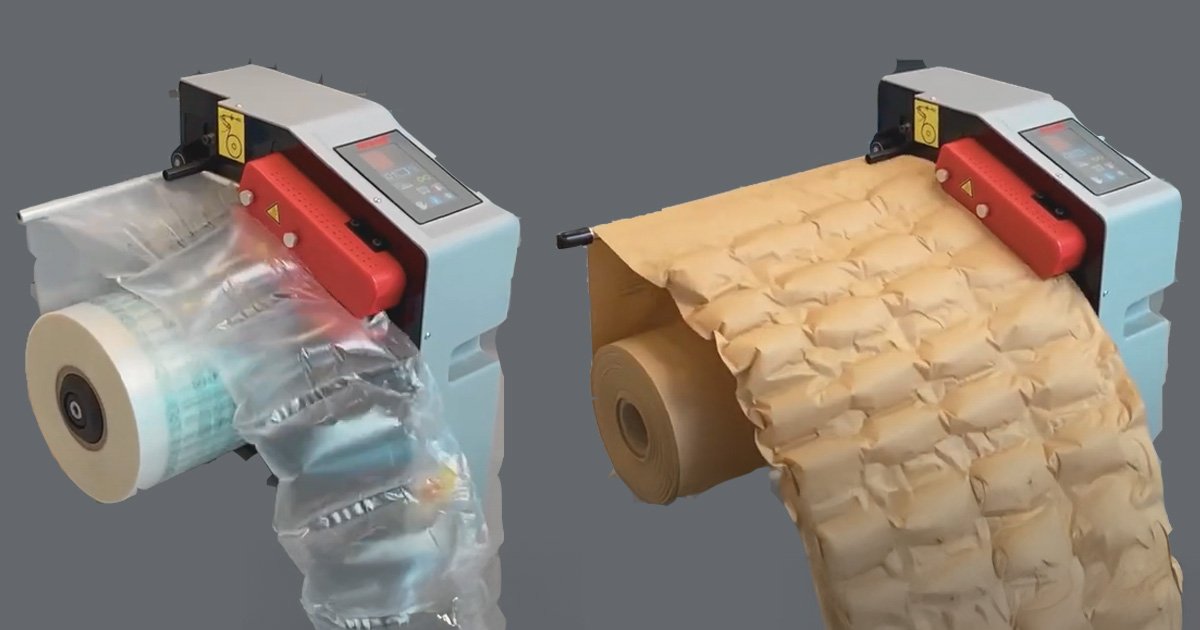

Air cushion systems use small, inflatable plastic bags made from polyethylene (PE) or similar films. Machines inflate rolls of film on demand, producing pillows that are sealed and perforated for easy separation. The cushions are extremely lightweight; a large volume of packaging contains mostly air, dramatically reducing shipping weight. Air cushions are commonly used for electronics, cosmetics and consumer goods. Modern systems allow operators to select different sizes and fill levels to match product requirements.

Key features of air cushion packaging:

- Light weight and space efficiency: Inflatable cushions reduce package weight, lowering shipping costs and fuel consumption. Rolls of film take up little storage space before inflation.

- On‑demand production: Machines like the FROMM AP1000 produce void fill, bubble‑on‑demand and air cushions in one compact unit. It has an adjustable air‑fill setting and patented sealing technology. On‑demand production eliminates the need to store bulky pre‑filled materials and ensures the right amount of padding is produced for each package.

- Flexibility: Air pillows come in various sizes and film blends to fit different packaging needs.

- Durability and shock absorption: Inflatable cushions provide superior shock protection for delicate and lightweight items.

- Recyclability: Many air pillows use high‑density polyethylene (HDPE) or other recyclable plastics; some include recycled content.

Paper Void Fill

Paper void fill systems use rolls of kraft or recycled paper that are crumpled or folded into pads. Machines compress and output the paper to create cushioning or blocking inside the box. Paper void fill is versatile and can be moulded around different shapes. Paper is made from renewable resources and is compostable or recyclable.

Key features of paper void fill:

- Renewable and recyclable: Paper comes from natural fibres and is easily recyclable or compostable. Both FROMM PC1000 and PC100 PaperPad machines uses 100 % recycled FSC‑certified paper, providing a sustainable alternative to plastic.

- Adjustable cushioning: The PaperPad machine has adjustable compression settings and five production modes (including automatic and on‑demand) for customized protection.

- Quiet operation: The PC1000 operates silently, making it suitable for close‑proximity work environments.

- Shock absorption: Paper pads can absorb shocks and vibrations effectively, locking products in place.

- No equipment needed (basic forms): For small operations, hand‑crumpled paper offers a low‑cost solution without machines.

Why Void Fill Matters

Product damage during transit is expensive. In addition to the direct cost of replacements, damaged goods can erode customer trust and increase carbon emissions due to returns and re‑shipping. Sustainable void fill reduces packaging waste and supports Canada’s move toward a circular economy. Choosing the right void fill helps procurement managers balance cost, protection and environmental goals.

Bonus: Discover How Switching to Fromm Airpad Cushions Reduced Electronics Shipping Damage by 25%

Benefits and Limitations of Air Cushion Packaging

Lightweight, Cost‑Efficient Logistics

Air cushion packaging is largely filled with air, dramatically reducing the weight of each package. This can lower shipping costs and carbon emissions. CS Packaging notes that air pillows are a light‑weight void fill option that helps keep shipping costs down. Because the film is flat before inflation, it takes little storage space, important for procurement managers optimizing warehouse operations.

High Protection and Clean Presentation

Inflatable cushions offer superior shock absorption and protect delicate items from impact. They also provide a cleaner packaging experience: customers do not experience messy explosions of packing peanuts, and shipping areas remain tidy. Air cushions prevent fillers from sticking to products, enhancing unboxing satisfaction.

Sustainability Considerations

Air cushions are typically made from polyethylene (PE) or HDPE films. Some manufacturers offer cushions with recycled content or biodegradable additives. The FROMM AP1000 machine supports recycled PE, biodegradable film and even paper‑based cushions, giving users a choice of materials. When using recyclable films, ensure you can collect and recycle the cushions after use; otherwise, they may contribute to plastic waste.

Limitations

- Plastic use: Even when recyclable, plastic cushions rely on fossil‑based polymers. Recycling rates for plastics remain low: Canada recycled only 9 % of its plastic waste in 2019.

- Equipment cost: Air cushion machines require an initial investment. However, the cost can be offset by savings in shipping and storage.

- Perceived sustainability: Some customers may perceive plastic packaging as less eco‑friendly, even if cushions are recyclable or reused.

Benefits and Limitations of Paper Void Fill

Sustainability and Consumer Appeal

Paper is derived from renewable resources and is widely recyclable. The PC1000 PaperPad machine uses 100 % recycled, FSC‑certified paper, aligning with corporate sustainability goals. Consumers increasingly favour brands that use eco‑friendly packaging; sustainable void fill can enhance brand image and customer loyalty.

Robust Protection and Versatility

Paper cushions offer excellent shock absorption. Ranpak notes that paper filler locks products in place and absorbs shocks. Because paper is mouldable, it can be shaped to fill irregular spaces and provide blocking, bracing and wrapping. The PaperPad PC1000 allows adjustable compression and multiple production modes, enabling precise cushioning for fragile items like glassware, electronics and machinery.

Operational Efficiency

With machines like the PC1000 producing up to 40 m/min of cushioning, paper systems can support high‑volume operations. Paper pads are silent, reducing noise in the packaging area. The PC1000 can integrate with IIoT connectivity for predictive maintenance, ensuring reliability.

Limitations

- Weight and bulk: Paper void fill is heavier than air cushions, which can increase shipping costs.

- Material use: Producing paper requires energy and water, and the kraft process can contribute to deforestation if not managed responsibly. However, recycled paper reduces this impact.

- Storage space: Large rolls of paper may require more warehouse space than uninflated film.

Comparative Analysis: Air Cushion vs Paper Void Fill

Environmental Impact

Canada’s Zero Plastic Waste Agenda aims to avoid plastic packaging, reduce excessive packaging and replace problematic plastics. Air cushions use less material than many alternatives but still rely on plastic. Paper pads are renewable and biodegradable, and the PC1000 uses recycled FSC‑certified paper. Yet paper production has its own environmental footprint (energy, water, and potential deforestation). Procurement managers should consider end‑of‑life scenarios: Can customers recycle cushions easily? Do they have access to composting facilities for paper?

Cost and Logistics

Air cushions are lighter, leading to lower shipping costs. They also take up less storage space and can be produced on demand, which reduces warehouse inventory and labour. Paper pads are heavier and bulkier but may offer savings in material cost if produced in‑house. Equipment costs for both systems should be compared: the AP1000 provides air cushions, bubble wrap and on‑demand void fill in one machine, while the PC1000 is dedicated to paper cushioning.

Protection and Customer Experience

Both solutions provide effective shock absorption. Air cushions excel at protecting lightweight, fragile items and offer a cleaner unboxing experience. Paper void fill provides a more organic look and feel that some customers may associate with sustainability; it also avoids issues with static electricity or plastic clinging to products. However, paper may produce dust or debris if not properly handled.

Efficiency and Flexibility

Air cushion systems like the AP1000 allow users to adjust air‑fill settings and produce different types of cushioning (void fill, bubble on demand, air cushions). They integrate easily into automated packing lines and support high‑speed operations. Paper systems such as the PC1000 also support automatic or manual modes and can adjust compression for different padding thicknesses. For warehouses with limited space or high throughput, the compact footprint and lightweight design of the AP1000 (weighing only 11.5 kg) may be advantageous.

Air Cushion vs Paper Void Fill Summary Table

Below is a concise comparison of air cushion and paper void fill across key criteria.

| Criteria | Air Cushion | Paper Void Fill |

| Material & Sustainability | Made from PE/HDPE; recyclable; some options include recycled or biodegradable content | Made from recycled, FSC‑certified paper; renewable and biodegradable |

| Weight & Logistics | Ultra‑lightweight; reduces shipping costs and storage space | Heavier; may increase shipping costs and require more storage |

| Production & Flexibility | On‑demand production; adjustable air‑fill settings; multiple cushion sizes | Adjustable compression and modes; multiple pad lengths and paper weights |

| Protection & Applications | Superior shock absorption for lightweight, fragile items; clean unboxing | Effective shock absorption; moulds around irregular shapes; natural look |

| Environmental Impact | Relies on plastic; recycling infrastructure needed; uses less material per package | Renewable and compostable; higher material mass; paper production has environmental footprint |

| Ideal Use Cases | Electronics, cosmetics, high‑volume fulfillment | Fragile items, glassware, eco‑conscious brands |

Trends and Market Insights

Growing Demand for Sustainable Packaging

The global market for air cushion packaging was valued at USD 3.81 billion in 2023 and is projected to grow at a 5 % CAGR from 2024‑2030. Growth is driven by e‑commerce and demand for sustainable packaging, which motivates companies to adopt lightweight, flexible packaging solutions. The void‑filling segment dominates this market, accounting for 33.2 % share in 2023.

Kraft paper packaging is also expanding. Market research predicts that the global kraft paper market will reach USD 18.7 billion by 2025 with a 3 % CAGR, as businesses seek renewable and recyclable materials. Sustainable packaging across all materials is booming: Canada’s sustainable packaging market had revenues of CAD $7.9 billion in 2023 (according to research reports), and worldwide, the sustainable packaging market is expected to double between 2023 and 2034.

Canada’s Zero Plastic Waste Agenda

Canada’s government introduced a Zero Plastic Waste agenda to address plastic pollution. Single‑use plastic items (e.g., polystyrene foam containers) are being phased out. A Pollution Prevention (P2) Notice aims to reduce primary food plastic packaging by requiring grocery retailers to prepare pollution prevention plans. Quick facts from Environment and Climate Change Canada show that Canadians threw away 4.4 million tonnes of plastic waste in 2019, only 9 % of which was recycled. Additionally, a 2023 audit found that 64 % of products in selected grocery sections were packaged in single‑use plastic, and single‑use food packaging represented more than a quarter of litter on Canadian shorelines.

These statistics highlight regulatory pressure and consumer expectations for sustainable packaging solutions. Procurement managers should anticipate evolving rules around recycled content, labeling and extended producer responsibility programmes.

E‑Commerce and Consumer Expectations

The rise of e‑commerce is fueling demand for efficient void fill solutions. Online shoppers expect fast delivery, intact products and minimal waste. Air cushions enable quick packing and shipping while keeping packages lightweight. Paper void fill satisfies consumers looking for eco‑friendly packaging. Businesses that align packaging practices with customer values can strengthen their brand and improve loyalty.

Choosing the Right Void Fill Solution

Selecting between air cushions and paper pads depends on your product characteristics, sustainability objectives, budget and operational constraints.

- Assess product fragility and weight. Air cushions provide superior protection for lightweight, fragile items and are ideal for electronics, cosmetics and pharmaceuticals. Paper pads offer strong bracing for heavier or irregularly shaped items and provide a natural appearance.

- Consider sustainability goals. If your organization prioritizes minimizing plastic, paper void fill may be more consistent with corporate environmental policies and customer expectations. However, using recyclable or biodegradable air cushions can also support sustainability—especially when combined with recycling programmes.

- Evaluate total cost of ownership. While air cushion machines require initial investment, they reduce shipping costs and storage space. Paper systems may involve lower equipment costs but higher material weight. Calculate costs per package considering material, labour, shipping and waste disposal.

- Integration with packaging lines. For high‑volume operations, automation and speed are vital. The AP1000’s adjustable settings, IIoT connectivity and ability to produce multiple types of cushions make it versatile. The PC1000 offers multiple modes and adjustable compression for customized paper pads. Consider how each system fits into your existing workflows.

- Regulatory compliance. Monitor Canadian regulations on plastic packaging, recycled content and labeling. Choosing paper or recyclable plastics that meet upcoming requirements can future‑proof your packaging strategy.

FROMM Solutions: Air Cushions and Paper Pads

FROMM Airpad AP1000

The AP1000 is a fourth‑generation void fill machine that produces air cushions, bubble‑on‑demand and void fill in one compact unit. It features adjustable air‑fill settings, patented sealing technology and an intuitive touchscreen. Benefits include reduced packaging costs, elimination of excess storage, improved efficiency and enhanced sustainability. The AP1000 weighs just 11.5 kg and operates at 20 m/min, making it ideal for decentralized packing stations.

FROMM PaperPad PC1000

The PC1000 PaperPad machine converts rolls of recycled paper into crumpled pads that fill voids and cushion products. Key features include a small footprint (650 × 402 × 348 mm), adjustable paper compression, five production modes (automatic, semi‑automatic, demand, etc.) and silent operation. It uses 100 % recycled FSC‑certified paper, and the pads are biodegradable and easily recyclable. The PC1000 can produce up to 40 m/min of cushioning and integrates with scanners and IIoT connectivity for high‑volume lines. Its safety features include a bladeless design and predictive maintenance.

Frequently Asked Questions (FAQ)

- What is the main difference between air cushions and paper void fill?

Air cushions are inflatable plastic pillows produced on demand that offer lightweight shock absorption. Paper void fill uses recycled kraft paper crumpled into pads to fill empty space and protect items. - Are air cushions recyclable?

Many air cushions are made from recyclable PE or HDPE film. Some contain recycled content or biodegradable additives. Check local recycling programmes to ensure proper disposal. - Is paper void fill more sustainable than plastic?

Paper is renewable, biodegradable and recyclable. However, it can be heavier and requires energy and water for production. The sustainability advantage depends on using recycled paper and ensuring end‑of‑life recycling or composting. - Which solution is better for high‑volume operations?

Both air cushion and paper systems offer high‑speed production. The AP1000 produces multiple packaging types on demand, while the PC1000 outputs up to 40 m/min of paper pads. Choice depends on product weight, space constraints and sustainability goals. - Do air cushion machines require special training?

Modern machines like the AP1000 feature intuitive touchscreens and manual or semi‑automatic modes. Training is straightforward, and the learning curve is minimal. - Can paper and air cushions be combined?

Yes. Many companies use a mix of air cushions for lightweight void fill and paper pads for blocking heavy items or adding a sustainable look. Fromm’s AP1000 can produce both air cushions and bubble‑on‑demand film, while the PC1000 provides paper pads, giving flexibility to tailor packaging. - How does void fill affect customer satisfaction?

Proper void fill ensures products arrive intact, reducing returns and increasing customer loyalty. Clean and sustainable packaging enhances brand perception and aligns with consumer values. - Are paper pads costlier than air cushions?

Paper is generally more expensive per unit than plastic film. However, paper pads are recyclable and may reduce environmental fees or align with brand values. Evaluate costs based on material, shipping weight and waste disposal.

Conclusion – Air Cushion or Paper Void Fill?

As Canada advances toward a circular economy and stricter plastic regulations, procurement and sustainability managers must rethink protective packaging. Air cushions offer lightweight, efficient protection and can reduce shipping costs, whereas paper void fill delivers renewable, recyclable cushioning that resonates with eco‑conscious consumers. The choice depends on your product mix, sustainability goals and operational priorities. FROMM Packaging Canada provides versatile solutions across both categories, from the Airpad AP1000 to the PC1000 PaperPad, each designed to optimize efficiency and reduce environmental impact.