Canadian shippers confront escalating regulatory demands for sustainable packaging, with extended producer responsibility programs launching across provinces like Ontario by 2026, potentially shifting billions in waste management costs. Non-compliance exposes businesses to fines exceeding CAD 10 million annually. This article delivers a step-by-step framework to audit practices, set goals, and implement eco-friendly solutions such as on-demand air cushioning systems.

What Are Sustainable Packaging Strategies?

Sustainable packaging strategies are comprehensive operational frameworks designed to minimize environmental impact while maintaining product protection integrity. These strategies prioritize source reduction, material recyclability, and supply chain efficiency. A core component involves “right-sizing,” which utilizes on-demand systems to produce the exact amount of void fill required, thereby eliminating excess material volume.

Effective strategies integrate Extended Producer Responsibility (EPR) obligations, ensuring that packaging materials—whether flexible films or paper—are compatible with provincial recycling infrastructure. This approach shifts focus from simple material substitution to a holistic lifecycle analysis, examining the carbon footprint from production through to end-of-life processing. It requires the selection of materials that support circular economy principles, such as high-quality polyethylene (PE) films capable of entering existing recycling streams.

Key Canadian Regulations and Trends Shaping 2026

The regulatory framework for 2026 is defined by strict oversight of plastic production and waste management. Canada’s proposed regulations mandate minimum post-consumer recycled content for categories by 2026, forcing manufacturers to adjust procurement specifications immediately (Government of Canada). This moves beyond theoretical targets to enforceable legal requirements affecting all levels of the supply chain.

Key regulatory trends include:

Extended Producer Responsibility (EPR): Producers are now financially and physically responsible for the end-of-life management of packaging.

Standardized Labelling: Strict rules regarding recyclability claims to prevent “greenwashing.”

Data Transparency: Mandatory reporting on resin types, additives, and material weight.

These regulations necessitate the adoption of packaging solutions with traceable data and certified recycled content.

Assessing Your Current Packaging Practices

An accurate assessment of current operations is the prerequisite for any strategic adjustment. This involves a granular audit of all packaging SKUs, consumption rates, and waste generation. The objective is to identify inefficiencies where material volume exceeds the structural requirements for product protection.

Packaging reduction opportunities exist where weight or volume can be lowered while maintaining function, providing immediate cost and environmental benefits.

The assessment must evaluate three critical areas:

Packaging reduction opportunities: Can the gauge (thickness) or dimensions of the film be reduced without compromising load stability?

Procurement practices: Are current materials certified renewable or do they contain verified recycled content?

Recyclability performance: Is the packaging compatible with the province’s sorting and recycling infrastructure and future EPR rules?

Step-by-Step Guide to Building Your 2026 Strategy

Developing a compliant strategy requires a systematic approach to data management and material selection. The following process ensures alignment with federal mandates and operational efficiency.

Step 1: Audit Materials and Waste

The initial step involves establishing a baseline through rigorous data capture. To comply with the Federal Plastics Registry, organizations must track plastic put on the market by resin, format, and sector by the 2026 reporting cycle. This requires cataloging every packaging component, from pallet wrap to void fill.

Audits must identify:

Resin Identification Codes (RIC): Verifying specific polymer types (e.g., PE, PET).

Material Origin: Distinguishing between virgin and post-consumer recycled (PCR) content.

Waste Streams: Quantifying the volume of material sent to landfill versus recycling centers.

Step 2: Set Measurable Sustainability Goals

Goals must be quantifiable and aligned with provincial EPR obligations. Targets should focus on specific metrics such as percentage reduction in total plastic weight or the transition of specific SKUs to 100% Recycled Content (PCR) films.

Key Performance Indicators (KPIs) for 2026:

Recycled Content: Achieving minimum PCR thresholds (e.g., 30% or 50%) in flexible films.

Volume Reduction: Decreasing cubic meters of void fill used per shipment through right-sizing.

Recyclability: Ensuring 100% of packaging materials meet local curbside acceptance criteria.

Lifecycle comparisons—analyzing damage rates and material weight versus expanded polystyrene (EPS)—provide the data necessary to justify these goals.

Step 3: Select and Test Solutions

Selection involves identifying machinery and consumables that meet the defined technical and environmental specifications. FROMM utilizes a 5-step process starting with a needs identification audit to ensure the proposed solution matches the throughput and protection requirements.

Testing protocols must validate:

Load Stability: Ensuring the reduced-material solution protects against shock and vibration.

Throughput Speed: Verifying that sustainable options do not bottleneck production lines.

System Integration: confirming compatibility with existing packing stations or conveyor systems.

Integration approaches often include 2D/3D drawings within two weeks to visualize the workflow optimization before implementation.

Top Eco-Friendly Void Fill and Protective Packaging Options

Industrial packaging solutions have evolved to offer high-performance protection with reduced environmental impact. The primary categories for sustainable void fill include on-demand air cushioning and paper-based systems.

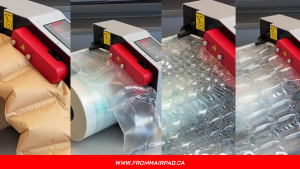

On-Demand Air Cushioning Systems

On-demand air cushion systems, such as the AP1000 All-In-One, drastically reduce material transport and storage requirements. These systems produce void fill at the point of use, meaning 99% of the volume is air and only 1% is material. This supports eco design principles on light weighting and reduces the total plastic tonnage per parcel.

Technical Specifications of AP1000:

Speed: 20 meters/minute (65.6 ft/min).

Material Compatibility: Processes PE, rPE (recycled), and Bio-films.

Control: Touch screen with patented no-contact sensor.

Airpad films are designed for the circular economy. They are made from recyclable plastic film and can be processed in existing recycling streams where compatible films are accepted.

Biodegradable and Recycled Alternatives

For applications requiring renewable materials, paper systems offer a robust alternative. The Paperpad PC100 converts 100% recycled, FSC-certified paper into high-volume cushioning. This aligns with strategies to pair plastic airpads with paper systems—using plastic where moisture resistance and weight savings are critical, and paper where fibre-based recyclability is preferred.

Film Material Comparison:

| Feature | Recycled Film | Bio-degradable Film | Paper |

|---|---|---|---|

| Composition | Post-consumer recycled PE | Bio-based polymers | 100% Recycled Kraft |

| Standard | ISO 14000 Certified | ASTM D6400 / EN 13432 | FSC Certified |

| Primary Use | General Void Fill | Eco-sensitive shipments | Heavy/Sharp items |

| Disposal | Recyclable (Stream 4) | Compostable (Industrial) | Curbside Recyclable |

Best Practices for Reducing Packaging Waste in E-commerce

E-commerce operations must balance speed with waste reduction. The most effective method for reducing waste is right-sizing, which involves matching the box size and void fill volume strictly to the product dimensions. Using smaller boxes plus on-demand void fill reduces corrugate consumption and eliminates over-spec foam or molded plastics.

Operational Best Practices:

Automated Scanning: Utilizing tools like the SmartFill scanner allows the machine to dispense the exact length of air cushions required for a specific box volume, removing operator guesswork.

IIoT Monitoring: The IIoT-Gateway™ connects machines to the cloud to monitor consumable usage and wear levels. This data visualization helps optimize material efficiency and prevent downtime.

Standardization: Limiting box sizes to a core set of dimensions allows for more precise calibration of void fill dispensing.

Regional Packaging Solutions Across Canada

Packaging requirements vary by region due to logistical distances and local industry composition. FROMM Packaging Systems Canada maintains a national network to support these diverse needs.

Toronto and Quebec: Void Fill Rentals and E-commerce Tools

The Central Canada corridor, encompassing Toronto and Quebec, represents a high density of e-commerce fulfillment centers. In these markets, high-speed automation and rental models are prevalent. The AP1000 and Paperpad PC100 are frequently deployed here to handle high-volume throughput.

Service Model: Rental and “Free-on-loan” agreements for machines are common, tied to consumable purchases.

Focus: Speed, reliability, and integration with conveyor systems.

Support: Proximity to the Pickering, ON headquarters ensures rapid technical service and parts availability.

Calgary, Ottawa, and Winnipeg: Protective and Waste-Reduction Options

In regions like Calgary, Ottawa, and Winnipeg, the focus often shifts towards industrial logistics and varied distribution needs. Here, the versatility of the equipment is paramount.

Application: Protection for heavy industrial parts and inter-provincial logistics.

Solution: Airpad systems capable of running heavy-duty films (e.g., multi-layer barrier films) provide necessary puncture resistance.

Sustainability: Emphasis on reducing freight weight through lightweight air cushions compared to traditional paper or loose fill, which is critical for long-haul shipping from Western distribution hubs.

Failures in sustainable packaging strategies often stem from a lack of data or misalignment with infrastructure.

Critical Errors:

Ignoring Infrastructure Reality: Selecting “compostable” plastics that local facilities cannot process. It is often better to select high-quality recyclable PE that fits existing EPR streams.

Over-Packaging: Continuing to use legacy foam or excessive layers of bubble wrap out of habit rather than testing reduced-material alternatives.

Data Gaps: Failing to record resin weights and types, leading to non-compliance with the Federal Plastics Registry.

Inconsistent Messaging: Making vague environmental claims without the technical data to back them up, risking violation of new labelling laws.

Conclusion

Planning for 2026 requires a technical, data-driven approach to packaging. By auditing current waste streams, aligning with federal EPR and registry requirements, and deploying on-demand systems like the AP1000 or Paperpad PC100, organizations can achieve compliance while optimizing operational costs. The transition to sustainable packaging is not merely a regulatory burden but an opportunity to refine logistics efficiency through light weighting and material reduction.

FROMM Packaging Systems Canada supports this transition with certified machinery, recyclable consumables, and the technical expertise required to navigate the evolving regulatory environment.

The AP1000 produces 99% air and 1% PE film at 20 meters/minute, reducing material volume by up to 80% versus pre-made bubble wrap. This right-sizing eliminates storage needs and supports EPR recyclability.

AP1000 can effectively replace traditional air cushions for most ecommerce applications. This air system provides superior moisture resistance, double sealed and lightweight compared to conventional bubble wrap or foam inserts.