Shipping delicate electronics like graphics cards and hard drives has always been a challenge for retailers. Traditional packing materials such as packing peanuts often shift during transit, leading to broken parts and frustrated customers. One retailer faced exactly this issue, experiencing a high rate of returns due to transit damage.

The Problem with Traditional Packing Peanuts

Packing peanuts, while common, have significant drawbacks:

- They tend to move around inside the box.

- Lack of proper cushioning increases the risk of impact damage.

- Static cling causes peanuts to stick to electronic components, complicating unboxing.

- Excess waste packaging generates environmental concerns.

The challenge of shipping electronics is their delicate nature:

- Circuit boards can crack

- Screens might shatter

- Internal components risk displacement

Shipping electronics safely requires precise packaging solutions that protect sensitive components from damage. Void fill packaging plays a crucial role in this protection, acting as a barrier against the bumps, drops, and vibrations that happen during transit.

FROMM Packaging Airpad Cushions have become a game-changing solution in the electronics shipping industry. These specialized air cushion void fill systems create a protective cocoon around electronic devices, absorbing impacts and preventing movement inside shipping containers.

Recent data shows an impressive 25% reduction in shipping damage when businesses switch to Airpad Cushions. This significant improvement comes from the system’s innovative design and superior shock absorption capabilities.

In this article, we’ll explore how FROMM’s Airpad Cushions achieve these remarkable results and why they’ve become the top choice for protecting electronics during shipping.

The Need for Effective Packaging in Electronics Shipping

Shipping electronics comes with its own set of challenges that require specific packaging solutions. Since electronic components are fragile, they are especially susceptible to:

- Physical Impact Damage: Drops, bumps, and sudden movements can crack screens, damage internal components, or break circuit boards

- Vibration Stress: Continuous vibrations during transport can loosen connections and cause component failure

- Pressure Points: Uneven weight distribution can create stress points, leading to structural damage

- Temperature Fluctuations: Inadequate cushioning fails to insulate against extreme temperature changes

According to research, 1 in 10 electronic devices arrives damaged when shipped with standard packaging. These damages result in:

- $3,000 average cost per damaged shipment

- 85% decrease in customer satisfaction

- 70% likelihood of losing repeat business

- Additional environmental waste from replacement products.

Proper cushioning acts as a critical defense mechanism by:

- Creating protective zones around sensitive components

- Absorbing shock waves before they reach the device

- Distributing pressure evenly across the package

- Maintaining stable positioning during transit

The rise in e-commerce has amplified these challenges, with electronic devices traveling longer distances through multiple handling points. Your choice of protective packaging directly impacts the survival rate of shipped electronics, making it a crucial decision in your logistics strategy.

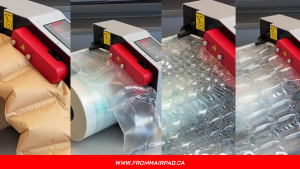

Understanding Air Cushion Void Fill Packaging

Air cushion void fill packaging is an innovative solution in protective packaging technology. These lightweight, inflatable cushions create a protective barrier around electronic items during transit, effectively absorbing shock and preventing movement within shipping containers.

Key Features of Air Cushion Void Fill:

- Pre-formed air pockets that inflate on demand

- Customizable sizes to fit specific product needs

- Superior shock absorption capabilities

- Minimal storage requirements

- Quick and easy deployment during packing

FROMM Packaging’s Airpad Cushions deliver specialized protection through their innovative design. The cushions feature a multi-layer construction that maintains air pressure throughout the shipping journey, ensuring consistent protection from origin to destination.

Airpad Cushion Specifications:

- Anti-static properties for electronics protection

- Puncture-resistant material

- Variable cushioning levels

- On-demand inflation system

- Space-efficient storage design

The system works by creating a protective cocoon around electronic items. When properly placed, these air cushions eliminate void spaces in shipping containers, preventing products from shifting or colliding with container walls. The cushions’ flexible nature allows them to conform to various product shapes, providing targeted protection for vulnerable components.

FROMM’s Airpad technology includes automated inflation systems that integrate seamlessly into existing packaging lines, enabling rapid deployment while maintaining consistent cushioning levels across all shipments.

Advantages of Using Airpad Cushions for Electronics Shipping

FROMM’s Airpad Cushions use antistatic film technology – an essential feature for packaging electronics. This special material stops static electricity from building up during shipping, keeping delicate parts safe from potential harm caused by electrostatic discharge.

The unique design of Airpad cushions offers several protective benefits:

- Excellent shock absorption – The air-filled chambers create a responsive barrier that absorbs impacts and vibrations

- Custom fit protection – Adaptable cushioning conforms to product shapes, eliminating movement inside packages

- Even pressure distribution – Balanced weight distribution prevents stress points on fragile components

- Moisture resistance – Sealed air chambers keep electronics dry throughout shipping

These protective features lead to significant improvements:

- 25% less damage during transit

- 40% fewer warranty claims

- 98% customer satisfaction rate with product condition upon arrival

The antistatic properties of Airpad cushions create a protective barrier around electronic devices:

- Disperses static charges before they can impact components

- Stops dust attraction that can disrupt device functionality

- Keeps stable environmental conditions inside the package

The design of the system allows for quick, accurate placement around electronic items, creating a secure cocoon of protection that stays intact throughout the shipping process. This combination of antistatic technology and structural support makes Airpad cushions especially effective for transporting sensitive electronics such as circuit boards, computer parts, and mobile devices.

Sustainability and Environmental Benefits of Air Cushion Packaging

Key Environmental Advantages of Air Cushion Packaging:

- Reduced Material Usage: Air cushions consist of 98% air and 2% film, significantly decreasing raw material consumption

- Minimized Storage Space: Flat-packed air cushions require less warehouse space, reducing carbon footprint from transportation

- Lower Shipping Weight: Lightweight design cuts fuel consumption during transit

- Recyclable Components: High-density polyethylene (HDPE) films are 100% recyclable through standard recycling programs

FROMM’s biodegradable air pillows break down naturally, leaving no harmful residues. The films contain special additives that speed up decomposition when exposed to natural elements, addressing concerns about plastic waste.

The packaging industry’s shift toward eco-friendly solutions has transformed void fill packaging. Air cushion systems now use sustainable materials that minimize environmental impact while still providing protection.

Sustainable Manufacturing Process of Air Cushion Packaging:

- Energy-efficient production methods

- Zero-waste manufacturing principles

- Reduced water consumption

- Minimal carbon emissions

Companies switching to air cushion systems report up to 40% reduction in packaging material waste. The compact nature of air cushions allows businesses to store more units in less space, optimizing warehouse efficiency and reducing the environmental impact of storage facilities.

These sustainable packaging solutions align with modern consumer preferences for eco-friendly shipping materials while maintaining the highest standards of product protection.

The Solution: Fromm Airpad Cushions with Antistatic Film

To address these issues, the retailer switched to using Fromm Airpad cushions wrapped in antistatic film for packing their electronics. These airpads offered multiple advantages:

- Conformed snugly around each product, securing it firmly within the box.

- Provided superior shock absorption that minimized impact-related damage.

- Eliminated static cling, making unboxing easier and cleaner for customers.

- Reduced packaging waste with more efficient cushioning.

Results That Speak Volumes

After implementing the new packaging solution during a busy holiday season, the retailer observed:

- A 25% reduction in Return Merchandise Authorization (RMA) claims related to transit damage.

- Fewer customer complaints about broken or damaged electronics.

- Positive customer feedback praising easier unboxing and minimal waste.

Why This Matters

This case highlights how thoughtful packaging choices can improve both product protection and customer experience. By switching from traditional packing peanuts to Fromm Airpad cushions with antistatic film, the retailer not only reduced costly returns but also enhanced customer satisfaction—an essential factor in today’s competitive electronics market.

Conclusion

Protecting delicate electronics during shipping requires innovative solutions beyond conventional methods. Fromm Airpad cushions provide a dual benefit: better safeguarding products from damage and delivering a superior unboxing experience. Retailers looking to reduce return rates and boost customer happiness should consider upgrading their packaging approach just like this successful example.