AP1000: All-in-One Air Cushion Packaging Machine for Void Fill, Bubble Wrap & Air Cushions

Features at a Glance

- Versatile protective packaging: Void fill, bubble-on-demand & air cushions

- Compact footprint for small office or warehouse spaces

- Lightweight design (weighs only 11.5 kg)

- Adjustable air-fill settings for precise cushioning

- Patented sealing technology for superior durability

- Intuitive touchscreen interface for easy operation

Top Benefits of the AP1000

✔ Reduce packaging costs with on-demand production

✔ Eliminate excess storage needs for pre-filled packaging

✔ Improve efficiency and meet high shipping demands

✔ Ensure product protection with custom air cushion solutions

✔ Enhance sustainability with eco-friendly packaging materials

- Machine Speed: 20 meters per minute (65.6 feet per minute)

- Weight: 11.5 kg (25.3 lbs)

- Dimensions (HxLxW): 430 x 390 x 360 mm (16.9 x 15.4 x 14.2 inches)

- Power Supply: 100-240V, 50/60 Hz

- Material Compatibility: PE film, recycled PE (rPE), biodegradable film, and paper-based cushions

- Sealing Technology: Two-side sealing for superior durability and strength

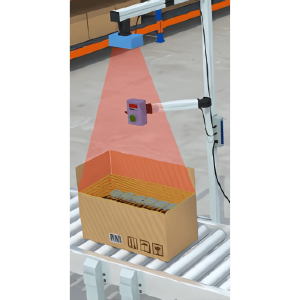

- End-of-Roll Detection: Patented no-contact sensor for uninterrupted operation

- Operation Mode: Manual or semi-automatic

- Adjustable Filling Rate: Custom air-fill settings for optimized cushioning

- Control Interface: Touchscreen panel for user-friendly operation

- Smart Monitoring: IIoT Gateway™ for real-time tracking and predictive maintenance

• Compact bin – 50.2134

• Hopper – 50.2135

• Winder – 50.2136

• Air cushion Separator – 50.2130

• SmartFill scanner – 50.100250

• Custom designed solutions

Use our tools to make the right choice :

- Free Guide – Fragile Shipments, Fewer Breaks. Your Essential Guide to Void Fill That Works.

- Product Finder – Explore your options

FAQs - Frequently Asked Questions ?

It reduces plastic waste by supporting recycled and biodegradable materials and producing only what’s needed through SmartFill

By producing air cushions, air pillows or bubble on demand only what is needed for your package or box, it eliminates excess wastage. Additionally, the compact design reduces storage space requirements, indirectly contributing to lower material handling costs.

Yes! The AP1000 is compact, modular, and easy to integrate into existing workflows.

Yes! Its fast production speed makes it perfect for high-demand industries.

The AP1000 void fill machine is ideal for shipping heavy-duty industrial products as it creates strong, impact-resistant air cushions that provide maximum protection during transit. Unlike traditional packaging materials, it utilizes high-strength, two-side sealed air cushions that effectively absorb shocks and vibrations, preventing damage to heavy items and ensuring safe delivery.

AP1000 void filling machine is ideal for electronics packaging due to their anti-static and high-cushioning properties.

The IIoT Gateway™ connects the Airpad AP1000 to the cloud, enabling real-time data visualization and analysis of machine condition, operation parameters, material usage, and wear levels. This optimizes uptime, efficiency, and service.

FAQs

The AP1000 is highly versatile and works with a wide range of materials, including PE, recycled PE (rPE), biodegradable films, and even paper, making it suitable for diverse packaging requirements and sustainability goals.

The AP1000 delivers rapid output, producing up to 20 meters (65.6 feet) of air cushions per minute, ensuring high productivity for busy packaging lines.

Yes, its compact design and small footprint make the AP1000 easy to integrate into any workspace or automated packaging line. FROMM also provides custom integration support, including 2D/3D layout drawings and tailored solutions.

The AP1000 features IIoT Gateway connectivity, enabling remote machine monitoring, predictive maintenance, and real-time data analysis to maximize uptime and efficiency.

It comes with a smart touchscreen for intuitive operation and a patented no- contact end-of-roll sensor, simplifying machine control and reducing operator intervention.

Yes, the AP1000 supports a variety of cushion sizes and patterns—up to 800mm in width—allowing for on-demand production of air cushions or bubble wrap tailored to specific packaging needs.

Absolutely. The AP1000 offers both manual and (semi-)automatic operation modes. It can also be paired with accessories like SmartFill scanners for calibrated, automated filling.

FROMM offers end-to-end project support, including needs assessment, system design, installation, commissioning, and ongoing maintenance. Their expertise ensures smooth integration and long-term reliability.

By supporting recycled and biodegradable films, as well as paper, the AP1000 helps reduce plastic waste and aligns with corporate sustainability initiatives.

The AP1000 weighs 11.5 kg (31.9 lbs), measures 430x390x360 mm, operates on 100-240V, and features adjustable filling rates, remote monitoring, and a range of accessories for customized setups

Yes, the FROMM AP1000 All-in-One Series Machine is fully compatible with both manual and automatic packaging lines. Its compact design allows for easy integration into any workspace, whether you require a standalone manual station or seamless incorporation into an automated packaging process. The AP1000 supports both manual operation—ideal for lower-volume or variable packing needs—and (semi-)automatic modes, making it highly adaptable to a wide range of packaging environments.

Tools to help you make the right choice

Free Guide – Fragile Shipments, Fewer Breaks

Learn how the right void fill approach can reduce damages, cut costs, and support sustainability. This free guide includes a Quick Self-Assessment Checklist to help you reflect on your needs.

Product Finder – Explore your options

Answer a few quick questions about your packaging needs and get personalised suggestions. The Product Finder helps you explore the options that could work best for your business.